Back in April 2002, the UK government legislated strict standards for building airtightness. This initiative was set in motion to achieve a range of goals: reducing operational costs, ensuring the quality of materials, components, workmanship, eradicating drafts, and preventing condensation issues.

Back in April 2002, the UK government legislated strict standards for building airtightness. This initiative was set in motion to achieve a range of goals: reducing operational costs, ensuring the quality of materials, components, workmanship, eradicating drafts, and preventing condensation issues.

Air permeability is a vital metric in determining how effectively a building is sealed from air seeping in or out, including through the windows, doors, and any openings. It quantifies the rate at which air can penetrate a building's structure.

In technical terms, it signifies the rate of airflow moving perpendicularly through a defined area of a building or building product, under a specified air pressure difference between the inside and outside of the building, or through the fabric of a building material. The higher the airtightness under a given pressure difference, the lower the infiltration.

This is expressed as the air leakage rate per hour per square metre of the building’s envelope area, tested at a reference pressure differential of 50 Pascal (50N/m²). In the UK, new homes are permitted to have a maximum allowable air permeability of 10 m³/h. m², a very good target is half of that.

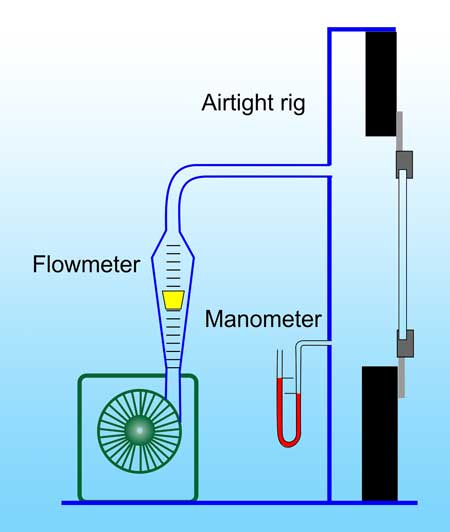

To assess the air permeability, a fan is typically integrated into the frame of the building, or a sample holder enclosing a building product. This fan is used to depressurize one side by extracting air. In the case of testing a building, the fan could, for example, be mounted in a door. The pressure difference this creates is then used to calculate the building's permeability. This procedure demands that fires are extinguished, doors and windows are securely closed, and ventilators sealed.

New buildings are subject to stringent energy calculations as mandated, in the UK, by Building Regulations. Specifically, for new dwellings, compliance with Part L of the Building Regulations necessitates the conduction of air pressure tests in accordance with ATTMA Technical Standard (ATTMA TSL1). Similarly, non-dwelling structures must adhere to ATTMA Technical Standard L2 (ATTMA TSL2). Product in a laboratory test need to follow BS EN 12114.

Beyond compliance, air tightness testing assumes a pivotal role in ensuring that the calculated Building Carbon Dioxide Emission Rate (BER) is lower than the Target Emission Rate (TER). This process is integral in achieving energy efficiency goals.

Beyond compliance, air tightness testing assumes a pivotal role in ensuring that the calculated Building Carbon Dioxide Emission Rate (BER) is lower than the Target Emission Rate (TER). This process is integral in achieving energy efficiency goals.

To test air permeability in a laboratory setting, a sequence of pressure difference steps (positive and/or negative) is applied across the specimen, and the airflow rate through the specimen is measured at each step. These are adjusted to reference conditions, resulting in a graph of air flow rate versus pressure difference. The leakage coefficients characterizing the building component are derived from the measured results.

Air tightness testing should ensure that the Building Carbon Dioxide Emission Rate (BER or DER) is below the Target Emission Rate (TER). The 'design air permeability' is the target value applied for calculating the TER, while the 'assessed air permeability' is the measured value crucial in establishing the BER (or DER).

Testing is compulsory for both new residential and non-dwelling developments, though buildings with a floor area less than 500m² may be exempt. In the absence of testing, an assessed air permeability of 15m³/h.m² must be used in calculations. On expansive developments, where a specific dwelling is not tested, the assessed air permeability is determined as the average test result from similar dwellings on the development, augmented by 2.0m³/h.m².